Tens of millions of springs

Jurvan Jousi spring designs can be found everywhere from air-conditioning units to nuclear power plants.

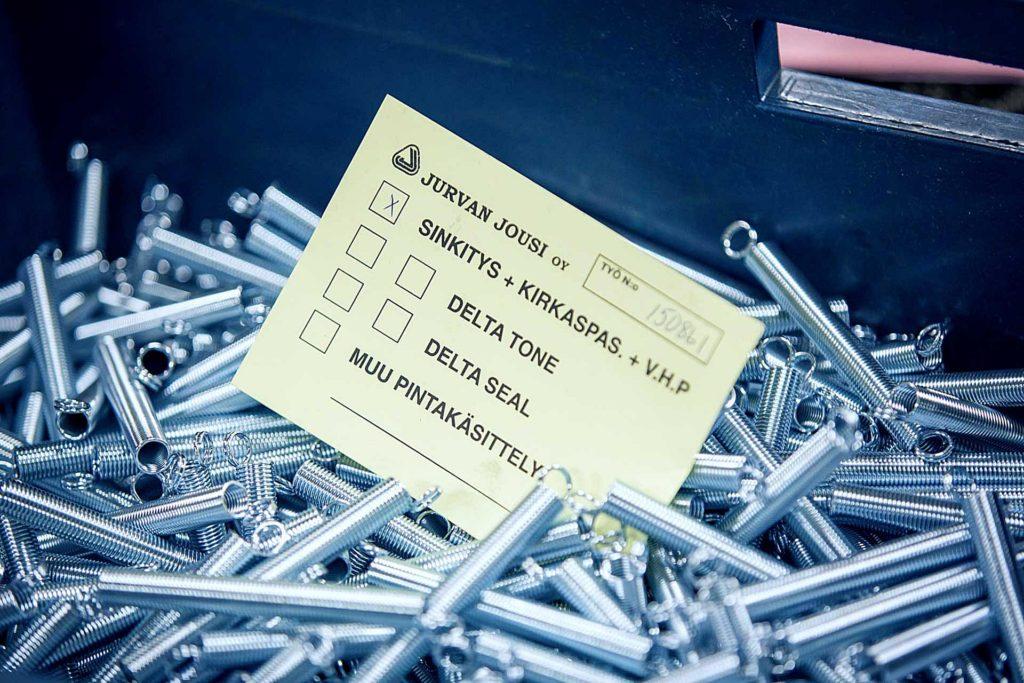

On an annual basis, Jurvan Jousi manufactures millions of extension, conical and compression springs. The wire machines produce torsion springs made to order, and the eccentric press makes flat springs and various flat parts.

According to Managing Director Jaakko Ojala, anything is possible for spring professionals. The team of 25 professionals can create any spring for machine workshops and electrical and electronics companies.

“Our springs can be found on the Hornet jet, for example. We have also manufactured springs for many products that are used under extreme conditions,” adds Sales Director Lasse Hahto.

Jurvan Jousi’s biggest customers include Wärtsilä, Abloy and Fläkt Woods. Approximately 15 per cent of products are exported directly. In reality, approximately 80 per cent of Jurvan Jousi’s springs end up abroad.

The current LED boom also reflects positively on Jurvan Jousi. The company manufactures LED fasteners, and orders keep rolling in at a nice rate.

Cutting-edge machines and competence

Established in 1975, the company can trace its success back to long partnerships and early investment in automation. The longest customer relationships date back to the 1970s.

“Back in the day, springs were made by hand, which was very slow compared to today’s pace. The only way to be internationally competitive is to invest in automation technology and to train professional and competent personnel. We can manufacture products with great volume and precision”, says Ojala, who has been in the spring business for 40 years now.

The company’s flexible operating structure also enables working in very fast cycles. This is a clear competitive advantage since the field requires quick reactions.

“People used to order large amounts of springs for up to a year’s needs. Today, batches are smaller and delivery must be quick,” says Ojala.

Hahto describes the progression of a smooth delivery process by explaining how the personnel participate by determining the optimal manufacturing time for the product.

“When a customer requests a quote, I walk into the industrial hall in the same building and request a delivery schedule. The professionals who operate the machines know best when I can promise to deliver the finished springs to the customer. They also commit to it, and the end result is quality work.”

Economic fluctuations have also influenced the activities of Jurvan Jousi. Ojala says that things are not quite back to the rate of the peak years of 2006–2007, but the turnover is growing well.

The company has invested in new machines every year. A million-euro investment is being planned for 2018. The story of Jurvan Jousi will continue going strong, since the next generation has already joined the company.